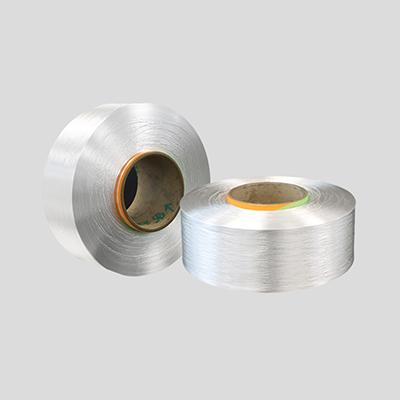

PEEK Filament: A Game-Changer in Customized Medical Implants

3D printing has revolutionized the way medical implants are manufactured. With the advent of PEEK filament, customized, patient-specific implants can be produced with high precision and excellent biocompatibility. Junsun Medical offers NATUREGEN® PEEK filaments, including the PEEK JS-S2 suitable for manufacturing personalized implanted devices.

Information

PEEK JS-S2 is designed for use in FDM technology and provides good melt fluidity, excellent mechanical properties, and high biocompatibility. The filament can be used to manufacture cranio-maxillofacial bone implants, trauma fixation plates, and dental implants that promote tissue reconstruction around the implant, resulting in faster osseointegration.

PEEK filament is highly resistant to chemicals, radiation, and heat, which makes it suitable for various sterilization methods, including steam sterilization. The material’s high weight-to-strength ratio and similarity to human bone make it an ideal material for manufacturing custom-made implants.

Moreover, the PEEK filaments produced by Junsun Medical meet rigorous quality standards, ensuring patient safety and device efficacy. The filaments are produced in compliance with ISO 13485 and ISO 9001 Quality Management Systems, and the material properties meet the requirements of ASTM F2006 and ISO 10993.

Conclusion

PEEK filament is a game-changer in the field of customized medical implants. The PEEK JS-S2 offered by Junsun Medical is designed for medical applications, providing excellent biocompatibility, mechanical properties, and resistance to wear and tear. The ability to produce patient-specific implants with high accuracy and reliability makes PEEK filament a popular choice for medical device manufacturers.