A Comprehensive Guide To HUAPIN CNC Machining

Looking to get your new product or project machined quickly and accurately? Look no further than the HUAPIN CNC machining service! Our experienced engineers are here to help you get your project started and keep it moving smoothly – no matter how big or small. So what are you waiting for? Contact us today to learn more!

Types of CNC Machining

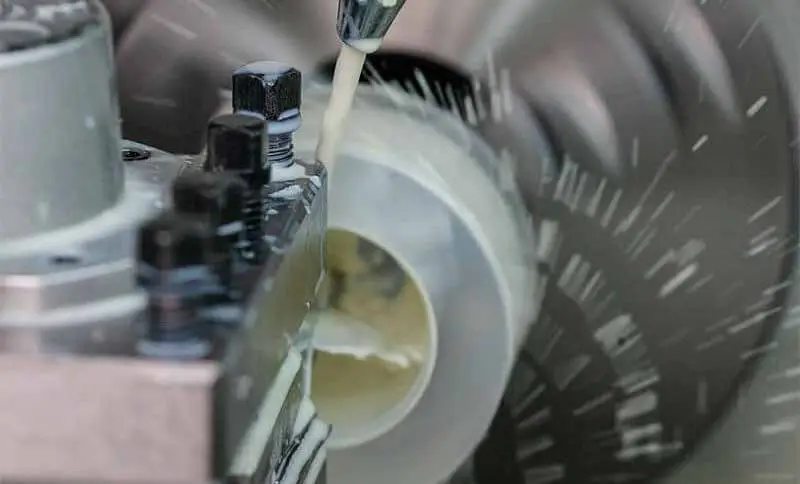

There are three main types of CNC machining: conventional, laser, and waterjet. Conventional CNC machining uses a rotary tool with a series of cutting tools that travel across the workpiece on an axis. Laser CNC machining uses a high-power laser to cut the part. Waterjet CNC machining service uses high-pressure jets of water to cut the part.

Each type of CNC machining has its benefits and drawbacks. Conventional CNC machining is the most common type used for most small parts. It is fast and accurate but can be slow and difficult for complex parts. Laser CNC machining is faster than conventional but requires more power and can’t handle complex parts well. For example, waterjet CNC machining is faster than both laser and conventional CNC machining but requires more water than either method.

Conclusion

If there is anything we could have done better, or if you have any questions, please don’t hesitate to let us know in the comments below. We would love to hear from you!